Transforming Production: A Closer Look at Gamayun AI-DTM

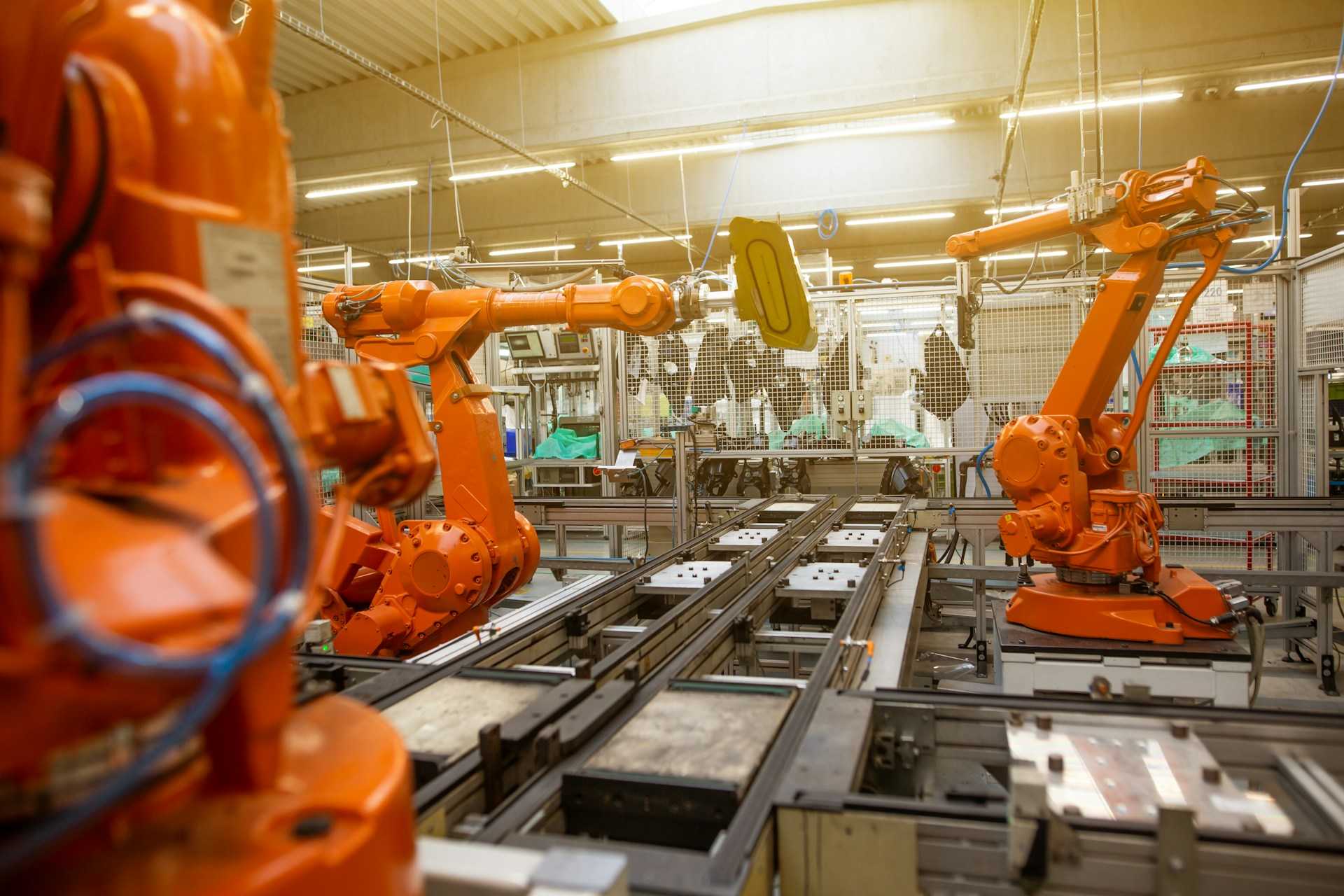

Harnessing AI and Digital Twins to Revolutionize Manufacturing

In our last post, we introduced the Gamayun AI-DTM (DTM - Digital Twin for Manufacturing) solution, showcasing how it uses artificial intelligence and digital twin technology to improve manufacturing. Today, we'll dive deeper into how this technology works and the real-world benefits it offers. These are also our own goals of what we want to achieve with this solution.

Implementation of Real-Time Digital Twin Technology

At the heart of Gamayun AI-DTM is its real-time digital twin technology. Think of digital twins as virtual copies of physical machines and systems. These digital replicas operate in real-time, constantly receiving data from their physical counterparts. By analyzing this data, digital twins can predict maintenance needs, optimize performance, and suggest improvements.

Gamayun AI-DTM uses an event-driven architecture, meaning it processes data and responds to changes instantly. For example, if a machine overheats, the system can immediately adjust its operation to prevent damage. This quick response helps prevent breakdowns and keeps the production line running smoothly.

Offering flexible solutions for different needs

Gamayun AI-DTM offers two main deployment options: Digital Twin as a Service (DTaaS) and Digital Twin as a Platform (DTaaP).

DTaaS is ideal for small to medium-sized businesses. It’s a cloud-based solution that scales easily and integrates with existing systems. It’s also easy to set up, thanks to a one-click installation process.

DTaaP is designed for larger enterprises that need more customization and integration. This model uses advanced cloud infrastructure to handle large-scale operations. It works well with both new and old systems, making it a versatile choice for complex manufacturing environments.

Predictive manufacturing insights

One of Gamayun AI-DTM's standout features is its ability to process and analyze large amounts of data from various sources, such as energy consumption and machine vibrations. This capability provides valuable insights that help improve decision-making.

Enhanced Data Processing: The system uses an event-driven architecture to handle diverse data streams. This setup reduces data processing time, making it faster to get useful insights. It also improves data utilization efficiency, leading to better and quicker decisions.

AI-Powered Decision-Making: Gamayun AI-DTM uses advanced AI models to enhance product quality, optimize resources, and predict manufacturing needs. These models improve decision-making and the accuracy of resource predictions.

Maximum integration and compatibility

One of the significant strengths of Gamayun AI-DTM is its seamless integration with both new and legacy systems. This flexibility ensures that manufacturers can adopt the technology without overhauling their existing infrastructure.

Easy integration: Gamayun AI-DTM is designed to work with a wide range of manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. The one-click installation process simplifies the setup, reducing the time and effort required to get the system up and running.

Scalability: Whether a small to medium-sized enterprise or a large multinational corporation, Gamayun AI-DTM can scale to meet the specific needs of the business. This scalability ensures that the system grows with the company, providing consistent benefits over time.

Building a resilient supply chain

Gamayun AI-DTM aims to foster a resilient supply chain by leveraging real-time data and AI-driven insights. The solution enhances collaboration between machine builders, AI solution providers, and end-users, creating a more integrated and responsive supply chain network.

Additionally, the integration of Gamayun AI-DTM supports sustainability by tracking production, resources, and energy efficiency in real-time. This real-time tracking enables better resource management and reduces environmental impact.

This combined approach not only strengthens the supply chain but also ensures that the benefits of Gamayun AI-DTM are widely adopted and sustained.

The future of manufacturing is here

Gamayun AI-DTM represents a transformative approach to manufacturing. It delivers significant benefits through real-time monitoring, predictive insights, and seamless integration, including improved efficiency, cost savings, and sustainability.

To sum up, let us point out the main Gamayun AI-DTM differentiation:

Open-source & customizable.

Transforms complex data into actionable insights (ML/AI inference).

Event-driven real-time data collection & processing.

Broad compatibility across CNC/PLC types & data formats.

Adopting Gamayun AI-DTM paves the way to a future of smarter, more efficient production for potential manufacturing clients. For more information about the solution please contact the Director of Sales, Mr. Bojan Miličić.

Photo by Simon Kadula on Unsplashu